For years, cadmium has been the solution of choice for corrosion protection and repairs in the aerospace sector.

However, as the industry knows, it’s damaging to the environment and toxic to humans, and so it is slowly being phased out. But when will it happen, and what will take its place?

We conducted a survey and found that only 23% of aerospace respondents believe they will be cadmium free by 2023. The reason, it seems, is a lack of credible and up-to-date research about what alternatives to use.

Most people don’t believe there’s anything suitable out there – or if there is, they’re not yet aware of it.

To help, we established the Cadmium Knowledge Hub. This resource includes detailed manufacturer reports and academic research papers into the topic of cadmium and cadmium replacements.

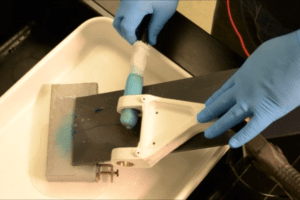

Here’s a very quick review of one of these investigations – a review of the suitability of four cadmium replacements to electrodeposited cadmium: IVD aluminum coating as well as alkaline zinc-nickel, acid zinc-nickel and tin-zinc plating.

Using cadmium as the control for some rigorous research activities, each replacement was subjected to seventeen separate tests, ranging from adhesion, lubricity and repairability through to fatigue and corrosion resistance. For the first time ever, the results allowed a direct comparison of the methods.

What conclusions did the report come to?

- The cadmium replacements evaluated in the tests can be confidently used without compromising performance

- Overall, alkaline zinc-nickel exhibits the best performance of the four cadmium replacements, and in terms of ratings, is very similar to cadmium

- IVD aluminum earns the second highest overall ratings compared with cadmium, followed by acid zinc-nickel and tin-zinc

- Against criteria which demanded that the coating should be ‘continuous, smooth, adherent, uniform in appearance, free from blisters, pits, nodules, burning, contaminants, excessive powder, and other apparent defects which could reduce serviceability or protection’, all cadmium alternatives were judged to be easily controlled and able to produce a suitable finish

- Placed in a neutral salt spray (fog) test cabinet for 3000 hours, none of the cadmium alternatives exhibited red rust or failure, demonstrating effective corrosion resistance

- Both alkaline zinc-nickel and IVD aluminium plating are easy to strip off and replate

- Alkaline zinc-nickel plating is an effective substitute for low-strength steel applications, while IVD aluminum is suitable for both low and high-strength steel applications

- For hazardous plating applications, alkaline zinc-nickel and IVD aluminum are effective alternatives to cadmium

- SIFCO ASC Zinc-Nickel LHE® has a pH of 8.8 and could be considered an alkaline Zi-Ni. It is an acceptable substitute for both low and high strength steel applications

- When using either a primer or primer and topcoat with brush plating, maximum paint adhesion is achieved with the use of a chromate conversion coating. This is true for all finishes, including cadmium.

For more information, visit the Cadmium Knowledge Hub.

Chinese (Simplified)

Chinese (Simplified)  English (UK)

English (UK)  French

French  German

German  Spanish

Spanish  Swedish

Swedish