As with many components in the Mold and Die industry, when wear occurs and pin and bushing dimensions deviate from needed tolerances, you may feel it is necessary to discard and replace core pins and core bushings.

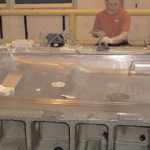

But not with selective plating. Reduce scrap and maintenance costs by resizing the core pins and bushing using the SIFCO Process® of selective plating. This in place repair also minimizes disassembly and downtime. Using a power pack and monitoring the digital ampere-hour meter, these parts can be selectively plated back to size, and put back in service, often without finish machining, all within one shift.

Nickel and Cobalt are excellent choices for selective deposition in these applications, since they have good toughness characteristics, in addition to excellent wear resistance. If a harder surface is required, nickel-tungsten, cobalt-nickel, and cobalt-tungsten alloys may be selectively deposited in a hardness range of Rockwell C 60 to 68.

Nickel and Cobalt are excellent choices for selective deposition in these applications, since they have good toughness characteristics, in addition to excellent wear resistance. If a harder surface is required, nickel-tungsten, cobalt-nickel, and cobalt-tungsten alloys may be selectively deposited in a hardness range of Rockwell C 60 to 68.

For more information on the SIFCO Process®, please contact us at info@sifcoasc.com or 800-765-4131.

Chinese (Simplified)

Chinese (Simplified)  English

English  French

French  German

German  Spanish

Spanish  Swedish

Swedish