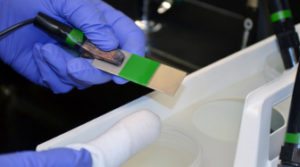

Brush plating (also known as selective plating) is a portable method of electroplating. Selective plating is used to apply anodized coatings and electroplated deposits in localized areas of a part without the use of an immersion tank.

Application and advantages

Brush Plating is primarily used for enhancing surfaces on OEM components, permanent repairs and salvaging worn or mis-machined parts. Because this method of electroplating is portable, it can be used anywhere in the shop or out on field, whereas traditional tank electroplating uses a bath or container to deposit the coating. Because of this, the process is used across a wide range of industries, including aerospace, oil and gas, marine, petrochemical and more.

The Benefits of Brush Plating

This method of surface plating provides a multitude of benefits, such as:

- Corrosion protection

- Improved wear resistance

- Improved solderability or brazing characteristics

- Decreased electrical contact resistance

- Galling prevention

- Serving as bearing surfaces

- Reduced downtime as machines don’t need to be taken apart

Chinese (Simplified)

Chinese (Simplified)  English (UK)

English (UK)  French

French  German

German  Spanish

Spanish  Swedish

Swedish