Selective Plating for the Aerospace Industry.

Without question, high-performance equipment is a necessity in the aerospace manufacturing industry. Aerospace components need to be able to withstand friction, high temperatures and corrosive environments while continuing to operate at optimum levels.

This is where repairing and enhancing the surfaces of your components can help, and selective plating offers a practical and cost-effective option to do so. At SIFCO ASC, we are a leading aerospace plating company providing electroplating technologies for OEM and MRO components that can improve performance.

Watch our video to find out more…

Common deposits utilized in aerospace manufacturing repair:

- Nickel is used for pre-braze operations, wear resistance, dimensional restoration and corrosion protection.

- Cadmium coatings for corrosion protection are available as LHE® (Low Hydrogen Embrittlement) formulations that do not require post-baking.

- Zinc-Nickel and other alloys are available as alternatives to cadmium coatings.

- Type I, II and III anodizing touch-up coatings are used to process components of engines, actuators, landing gear and airframes, increasing their ability to perform and extending overall in-service life.

- Cobalt Chromium Carbide provides superior wear resistance and high temperature oxidation protection on engine components.

- AeroNikl® – a sulfamate nickel which provides a defect-free, adherent, high quality nickel deposit that is available in three hardness levels (250, 400, and 575 Hv).

Common Aerospace Manufacturing Process Applications

Here are five common uses of selective and brush plating found in aerospace manufacturing and repair:

Corrosion Protection

To help you save on downtime, being able to make repairs in place and with minimum to no disassembly required is key. This is where on-site touch up coatings for corrosion protection with Cadmium LHE®, Cadmium No Bake and Zinc-Nickel LHE® can make a real impact. SIFCO ASC offers portable touch-up kits for AOG repairs of cadmium, nickel, zinc-nickel, and tin-zinc.

Pre-Braze

Turbine blades, turbine vanes, turbine stators and frames are nickel plated to ensure proper wetting of the surfaces to be brazed. Compared to other methods of applying the intermediate nickel layer, selective plating is faster, more consistent, and more cost effective. Selective plating for pre-braze also provides an atomic bond and superior wettability as compared with nickel shot blasting. In the case of exotic alloys, such as Renes and Inconels, selective plating is the preferred method of pre-brazing.

Surface Enhancement

OEM applications use nickel or a nickel alloy to improve hardness and wear resistance of the component.

Refurbishment

MRO applications use nickel or sulfamate nickel for dimensional restoration of an inside or outside diameters of the component.

Anodizing Touch-Up

Repair applications can replace worn or damaged coatings with a new anodizing seal. Selective anodizing touch-up is also offered for OEM applications. Find out more about 6 real-life applications of critical aerospace repairs here.

The SIFCO Process is approved by multiple primes, including Bell, Sikorsky, Boeing and more.

Applications for Aerospace Components

- TURBINE STATOR: Inner and outer stator and seal diameters are plated with 5µm to 20µm (0.0002 in. to 0.0008 in.) thickness of AeroNikl® 250 7280 for prebraze at the repair facility. The ability to selectively apply the prebraze deposit in-house, without the need for immersion tanks saves time, money and minimizes any potential environmental issues associated with large tank plating operations.

- TURBINE FRAMES: These components have been plated with 5µm to 15µm (0.0002 in. to 0.0006 in.) thickness of AeroNikl® 250 7280 for pre-braze on a contract basis by SIFCO ASC for over 5 years, providing a quick turnaround time. These parts were originally tank plated and required an extensive and time-consuming masking operation. The use of selective plating on these parts has eliminated the need for complicated masking and significantly reduced the turnaround time for each part.

- TURBINE BLADES: SIFCO ASC’s Contract Service Department has processed well over 20,000 OEM second stage blades, which previously were tank plated. Utilizing selective plating for this pre-braze application provided considerable savings to the customer and a much faster turnaround time.

- COMPRESSOR SPACERS AND TORQUE CONE FLANGES: Repair of worn bolt holes with a nickel build-up of 125µm (0.005 in.) using Nickel Ductile 2088. This material was selected because it matches the hardness of the substrate material.

- LANDING GEAR: Touch-up with Cadmium LHE® and Cadmium No Bake for corrosion protection can be done at the customer site, saving disassembly cost.

- MAIN LANDING GEAR OUTER CYLINDER: CVGP (Controlled Velocity Gap Plating) has made it possible for orifice tube boss ID’s to be repaired with thicknesses ranging from 250µm to 750µm (0.010 to 0.030 in.), with a tolerance range of 50µm (0.002 in.). Deposits of 750µm (0.030 in.) can be applied in approximately two hours. Tank plating, for the same repair, requires the part to be immersed for extended periods (24 to 72 hours is common) for the required deposit thickness. Machining is then required because of the excessive edge build-up. Immersion tank plating also requires very time consuming and careful masking.

Plating on Titanium

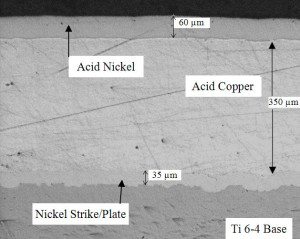

The SIFCO Process® enables you to selectively plate deposits onto Ti 6-4 and Ti 6-6-2 to improve the surface properties of localized areas on aerospace components for either OEM or repair applications. The technology optimizes the adhesion of the deposit to titanium alloys by removing titanium’s passive oxide and micro-roughening to increase surface area.

This micrograph shows a Ti 6-4 Grade 5 base plated with 0.0014″ of nickel, followed by 0.014″ of copper that is capped with 0.0023″ of nickel. Selectively plated deposits consistently meet the adhesion requirements of AMS 2451 and ASTM B 571 (bend test method), with no hydrogen embrittlement per GM 3661P. Additionally, selectively plated deposits exhibit adhesion in excess of 6000 psi in tensile pull tests.

Specific deposits can be selectively plated to a precise thickness to meet your engineering requirements.

With an adherent base layer of nickel, many additional deposits can be selectively plated to a precise thickness for:

Chinese (Simplified)

Chinese (Simplified)  English (UK)

English (UK)  French

French  German

German  Spanish

Spanish  Swedish

Swedish