Wear and tear on molds, and the need for repairs, are a regular cost of doing business. However, these costs can be reduced if the appropriate repair method is used.

In the automotive industry, several kinds of fiber and plastic matrices are being used in compression and resin transfer molding processes for everything from body parts to internal components. These molds can be quite expensive and have long lead times to make, therefore ensuring a timely repair when issues arrive is imperative.

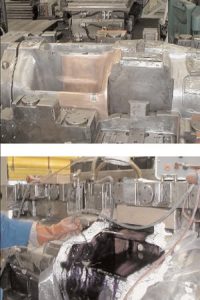

Damage to molds and related tooling is inevitable due to foreign objects getting into the cavities, acidic corrosion, and other causes of wear and tear, but these small flaws could cause unacceptable scrap rates. Which was the case with the fender mold of one automaker. Due to pitting in a small area at the bottom of the mold, their scrap rate rose from 2% to 15%.

The automaker was able to use selective plating to repair the area within one operating shift, preventing the mold from being taken out of service. (As a general rule, any defect depths of up to .06” are quality candidates for a selective plating repair.) If a mold has a lot of corrosion, scratches and other small surface flaws that result in a poor finish, selective plating can repair the damaged area in-situ, without removing the part or the need for extensive masking. This greatly reduces repair costs; and the end result is reduced rework and scrap rate costs.

Chinese (Simplified)

Chinese (Simplified)  English

English  French

French  German

German  Spanish

Spanish  Swedish

Swedish