Making Aircraft Maintenance More Cost Effective with Selective Plating Technology

Aeroplanes face harsh environmental conditions every day which makes efficient and effective aircraft maintenance and repair key to the success of industry. Conditions such as atmospheric moisture, high altitude, and temperature changes can all cause corrosion more quickly. This can result in structural damage, reduce the performance of critical components, and compromise safety. This is […]

Read More

Read More

What is a Copper Plating Certification and Why Does It Matter to the Oil and Gas Industry?

With extreme oil and gas supply shortages looming ever closer and the Strategic Petroleum Reserve of the United States reaching its lowest level in 38 years, oil and gas equipment needs to run as smoothly as possible. But, when two stainless steel parts of a threaded coupling are in direct contact with one another it […]

Read More

Read More

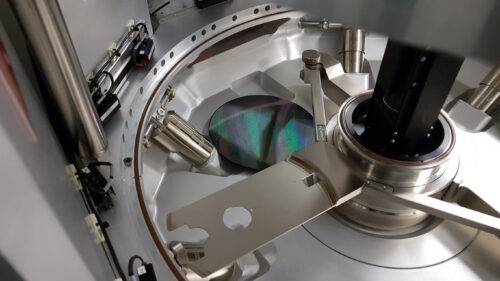

Selective plating, is it the answer to semiconductor shortages?

Between credit and debit card issuers to the automotive and technology sectors, many industries are being affected by a global semiconductor shortage. This was partially down to a demand spike in the pandemic as well as supply-chain issues. According to the American Machinist “The pandemic highlighted how semiconductor suppliers were ill-prepared for shocks, as some […]

Read More

Read More

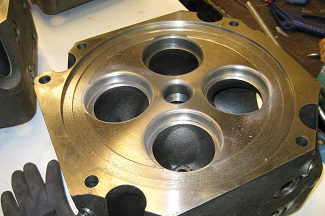

Localized Transmission Case Repair Salvages Critical Component

The job of any vehicle’s transmission is to change gears to ensure the engine’s RPM’s are kept low (depending on speed and acceleration). When the vehicle’s transmission is in working order, fuel consumption is decreased, and the turning of the gears does not overload the engine. With unpredictable environments and severe conditions, off-highway vehicle transmissions […]

Read More

Read More

In-situ Repair Maintains Critical Alignment

As with many machines, alignment of gears and components is critical. So, when even one component becomes out of round or out of tolerance, it can jeopardize not just the machine, but the entire operation with the threat of downtime and costly repairs. Unfortunately, the largest coal mining operation in Kalimantan, Indonesia, experienced just this […]

Read More

Read More

Restoring Tolerance to Wheel Hub Bolt Holes

Off highway vehicles face demanding environments. And every component of that vehicle is essential. For the largest coal mining operation in Kalimantan, Indonesia, that critical component was a wheel hub assembly. The wheel hub assembly allows the vehicle to steer freely, and is critical to the anti-lock braking and traction control systems. But when a […]

Read More

Read More

Selective plating – a quick and sustainable fix for long-term mining challenges.

Now more than ever, the mining industry needs cost-effective solutions to meet the long-term challenges presented by harsh environments, rising costs and increased environmental pressures. Mining’s off-road equipment and vehicles have to cope with extreme temperatures and harsh operating conditions including water and dust, as well as heavy duty cycles and vibration, all pushing machines […]

Read More

Read More

Reducing Variability by 80% with Flow Plating

FAMAT, an equally owned subsidiary of Safran Aircraft Engines and GE, based in St. Nazaire, France, is a world leading manufacturer of aircraft engine casings. FAMAT has a focus on providing solutions which are not only reliable and robust, but increasingly weight efficient and environmentally responsible. Demanding aerospace operating conditions present continual surface finishing challenges […]

Read More

Read More

Solving the Issue of Deep Bores and Non-line of Sight Areas

Heat exchangers are used throughout various industries to transfer heat from one fluid to another. Often, these fluids are corrosive to metal, making it important that components are protected against galvanic chemical damage. In this particular application, the heat exchangers were made of multiple steels including carbon steel, Inconel cladding, and stainless steel – increasing […]

Read More

Read More

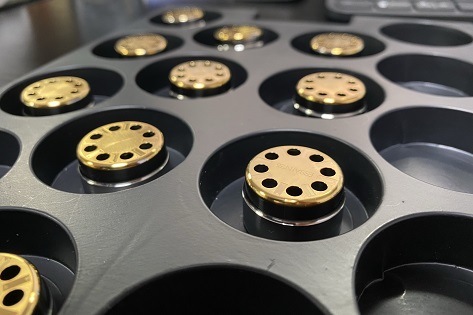

Complex Geometries, Custom Masking

The world-leader in the development and manufacture of cutting-edge location sensor technology approached SIFCO ASC for assistance with gold plating their resonators. Their high-performance accelerometers, gyroscopes and other systems are designed to meet the stringent requirements of customers for precision guidance, stabilization, navigation and orientation applications. To meet the specifications and maintain the repeatability and […]

Read More

Read More

Chinese (Simplified)

Chinese (Simplified)  English (UK)

English (UK)  French

French  German

German  Spanish

Spanish  Swedish

Swedish